Skip to content

- Truong-Le, Q. A., Lee, S. O., & Ubeyitogullari, A. (2025). Encapsulation of Bifidobacterium bifidum into a pH-sensitive alginate-pectin gel system using 3D food printing: enhanced viability and targeted release. International Journal of Biological Macromolecules, 145134.

- Barekat, S., & A. Ubeyitogullari. (2025). Developing hydrophobic-hydrophilic protein structures by 3D food printing of sorghum and soy protein gels. Journal of Food Engineering, 400, 112640. https://doi.org/10.1016/j.jfoodeng.2025.112640

- Kaur, J., & A. Ubeyitogullari. (2025). Recent Advances in the Utilization of Cellulose from Food Processing Byproducts for the Generation of Aerogels. Gels. 11(5), 359; https://doi.org/10.3390/gels11050359

- Kaur, S., J. Chen, & A. Ubeyitogullari. (2025). Transforming Soy Proteins Into Nanoporous Aerogels Using Supercritical Carbon Dioxide Drying. Sustainable Food Proteins, 3(2), e70011. https://doi.org/10.1002/sfp2.70011

- Tuhanioglu, A., Kaur, S., De Barros, G. L., Ahmadzadeh, S., Threlfall, R., & Ubeyitogullari, A. (2025). Optimizing Ethanol–Water Cosolvent Systems for Green Supercritical Carbon Dioxide Extraction of Muscadine Grape Pomace Polyphenols. ACS Omega. https://doi.org/10.1021/acsomega.4c10115

- Sadaf, N., Tuhanioglu, A., Ahmadzadeh, S., & Ubeyitogullari, A. (2025). Enhancing In Vitro Digestibility and Volatile Profile of Sorghum Proteins Using Supercritical Carbon Dioxide Drying. ACS Food Science & Technology, 5(1), 317-326. https://doi.org/10.1021/acsfoodscitech.4c00856

- Barekat, S., & Ubeyitogullari, A. (2025). Maximizing sorghum proteins printability: Optimizing gel formulation and 3D-printing parameters to develop a novel bioink. International Journal of Biological Macromolecules, 300, 140245. https://doi.org/10.1016/j.ijbiomac.2025.140245

- Nguyen, T. T., Ahmadzadeh, S., Schöberl, H., & Ubeyitogullari, A. (2025). Optimizing Printability of Rice Protein-Based Formulations Using Extrusion-Based 3D Food Printing. Food Science & Nutrition, 13(1), e4713. https://doi.org/10.1002/fsn3.4713

- Kaur, S., & Ubeyitogullari, A. (2024). The impact of supercritical carbon dioxide processing on the aroma and physicochemical properties of soybean flour. Future Foods, 100476. https://doi.org/10.1016/j.fufo.2024.100476

- Ahmadzadeh, S., Sagardui, A., Huitink, D., Chen, J., & Ubeyitogullari, A. (2024). Cellulose–Starch Composite Aerogels as Thermal Superinsulating Materials. ACS Omega, 9(50), 49205-49213. https://doi.org/10.1021/acsomega.4c05840.

- De Barros, G.L., Silva, F.T.S., Teixeira, R.S., Wagner, J.G., Rombaldi, C.V., Vizzotto, M., Ubeyitogullari, A., & Nora, L., (2024). Anthocyanin extraction methods: synthesis of morpho-anatomical knowledge for decision-making based on decision-tree. International Journal of Food Properties, 27(1), 1315-1346. https://doi.org/10.1080/10942912.2024.2409893.

- De Barros, G. L., Tuhanioglu, A., Kaur, S., Nora, L., & Ubeyitogullari, A. (2024). Extraction of anthocyanins from purple sweet potato using supercritical carbon dioxide and conventional approaches. Applied Food Research, 4(2), 100505. https://doi.org/10.1016/j.afres.2024.100505

- Tuhanioglu, A., & Ubeyitogullari, A. (2024). Application of supercritical carbon dioxide to enhance the aroma of whole sorghum flour for use in 3D printing of sorghum cookies. Food Research International, 190, 114588. https://doi.org/10.1016/j.foodres.2024.114588

- Kaur, S., & Ubeyitogullari, A. (2024). In vitro digestion of starch and protein aerogels generated from defatted rice bran via supercritical carbon dioxide drying. Food Chemistry, 139833. https://doi.org/10.1016/j.foodchem.2024.139833

- Lenie, M. D. R., Ahmadzadeh, S., Van Bockstaele, F., & Ubeyitogullari, A. (2024). Development of a pH-responsive system based on starch and alginate-pectin hydrogels using coaxial 3D food printing. Food Hydrocolloids, 153, 109989. https://doi.org/10.1016/j.foodhyd.2024.109989

- Ahmadzadeh, S., & Ubeyitogullari, A. (2024). Lutein encapsulation into dual-layered starch/zein gels using 3D food printing: Improved storage stability and in vitro bioaccessibility. International Journal of Biological Macromolecules, 266, 131305. https://doi.org/10.1016/j.ijbiomac.2024.131305

- Ahmadzadeh, S., Clary, T., Rosales, A., & Ubeyitogullari, A. (2024). Front Cover: Cover image. Food Science & Nutrition, 12(1). https://doi.org/10.1002/fsn3.3978

- Sadaf, N., Tuhanioglu, A., Hettiarachchy, N., & Ubeyitogullari, A. (2024). Effect of a novel drying method based on supercritical carbon dioxide on the physicochemical properties of sorghum proteins. RSC advances, 14(9), 5851-5862. https://doi.org/10.1039/D3RA07426A

- Hamilton, A. N., Mirmahdi, R. S., Ubeyitogullari, A., Romana, C. K., Baum, J. I., & Gibson, K. E. (2024). From bytes to bites: Advancing the food industry with three-dimensional food printing. Comprehensive Reviews in Food Science and Food Safety, 23(1), 1-22. https://doi.org/10.1111/1541-4337.13293

- Kaur, S., Chen, J., & Ubeyitogullari, A. (2024). Formation of nanoporous aerogels from defatted rice bran via supercritical carbon dioxide drying. Sustainable Food Technology, 2, 152-161 https://doi.org/10.1039/D3FB00069A

- Ahmadzadeh, S., Clary, T., Rosales, A., & Ubeyitogullari, A. (2024). Upcycling imperfect broccoli and carrot to healthy snacks using an innovative 3D food printing approach. Food Science & Nutrition, 12(1), 84–93. https://doi.org/10.1002/fsn3.3820

- Ahmadzadeh, S., Lenie, M. D.R., Mirmahdi, R.S., & Ubeyitogullari, A. (2023). Designing future foods: Harnessing 3D food printing technology to encapsulate bioactive compounds. Critical Reviews in Food Science and Nutrition. https://doi.org/10.1080/10408398.2023.2273446

- Tuhanioglu, A., Lafontaine, S., & Ubeyitogullari, A. (2023). Enhancing the Aroma of White Whole Sorghum Flour Using Supercritical Carbon Dioxide. Future Foods. 8:100253. https://doi.org/10.1016/j.fufo.2023.100253

- Tuhanioglu, A., Mauromoustakos, A., & Ubeyitogullari, A. (2023). Purifying Waxes Through Selective Extraction of Triacylglycerols from a Bioethanol Production Side-Stream Using Supercritical Carbon Dioxide. The Journal of Supercritical Fluids. 202:106059. https://doi.org/10.1016/j.supflu.2023.106059

- Ahmadzadeh, S., Hettiarachchy, N., Luthra, K., Chen, J., Seo, H. -S., Atungulu, G. G., & Ubeyitogullari, A. (2023), Effects of polyphenol-rich grape seed and green tea extracts on the physicochemical properties of 3D-printed edible soy protein films. Food Packaging and Shelf Life, 40, 101184. https://doi.org/10.1016/j.fpsl.2023.101184

- Ahmadzadeh, S. & Ubeyitogullari, A. (2023). Enhancing the stability of lutein by loading into dual-layered starch-ethyl cellulose gels using 3D food printing, Additive Manufacturing, 69, 103549. https://doi.org/10.1016/j.addma.2023.103549

- Kaur, S., & Ubeyitogullari, A. (2023). Extraction of phenolic compounds from rice husk via ethanol-water-modified supercritical carbon dioxide. Heliyon, 9 (3), e14196. https://doi.org/10.1016/j.heliyon.2023.e14196

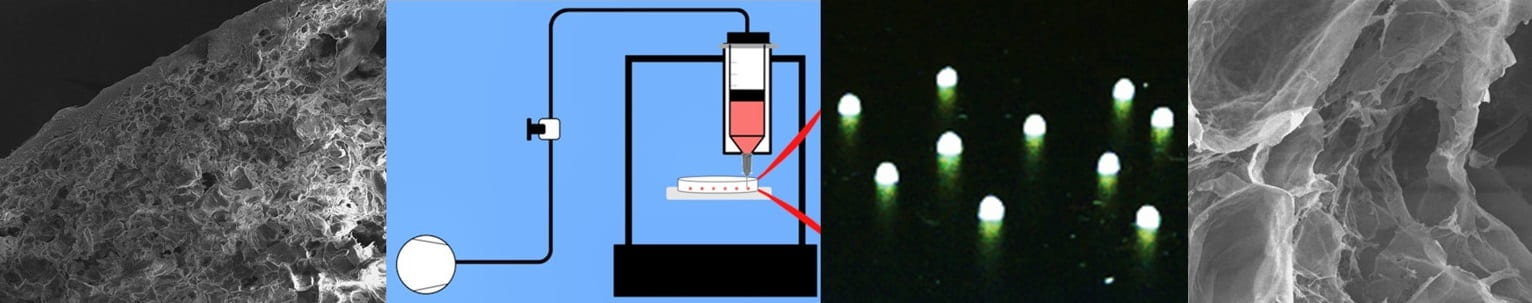

- Rysenaer, V. B. J., Ahmadzadeh, S., Bockstaele, F. V., & Ubeyitogullari, A. (2023). An extrusion-based 3D food printing approach for generating alginate-pectin particles. Current Research in Food Science, 6, 100404. https://doi.org/10.1016/j.crfs.2022.11.023

- Tuhaniogulu, A. & Ubeyitogullari, A. (2022). Extraction of high-value lipids and phenolic compounds from sorghum bran via a sequential supercritical carbon dioxide approach. ACS Food Science & Technology, 2, 1879-1887. https://doi.org/10.1021/acsfoodscitech.2c00266

- Ahmadzadeh, S. & Ubeyitogullari, A. (2022). Generation of porous starch beads via a 3D food printer: The effects of amylose content and drying technique. Carbohydrate Polymers, 301, 120296. https://doi.org/10.1016/j.carbpol.2022.120296

- Ubeyitogullari, A., Ahmadzadeh S., Kandhola, G., & Kim, J.-W. (2022). Front Cover: Cover Image. Comprehensive Reviews in Food Science and Food Safety, 21(6). https://doi.org/10.1111/1541-4337.13100

- Ubeyitogullari, A., Ahmadzadeh S., Kandhola, G., & Kim, J.-W. (2022). Polysaccharide-based porous biopolymers for enhanced bioaccessibility and bioavailability of bioactive food compounds: Challenges, advances, and opportunities. Comprehensive Reviews in Food Science and Food Safety, 21(6), 4610-4639. https://doi.org/10.1111/1541-4337.13049

- Dey, S., Hettiarachchy, N., Bisly, A. A., Luthra, K., Atungulu, G. G., Ubeyitogullari, A., & Mozzoni, L. A. (2022). Physical and textural properties of functional edible protein films from soybean using an innovative 3D printing technology. Journal of Food Science, 87(11), 4808-4819. https://doi.org/10.1111/1750-3841.16349

- Ahmadzadeh S., & Ubeyitogullari A. (2022). Fabrication of porous spherical beads from corn starch by using a 3D food printing system. Foods, 11(7):913. https://doi.org/10.3390/foods11070913